Chemical Safety Awareness Course Overview:

A Chemical Safety Awareness Course is designed to educate individuals about the potential hazards associated with handling and working with chemicals. The course aims to promote a safe working environment and ensure that participants understand the necessary precautions to prevent accidents and injuries. Below is a general outline of course contents for a Chemical Safety Awareness Course:

Chemical Safety Awareness Course Objective:

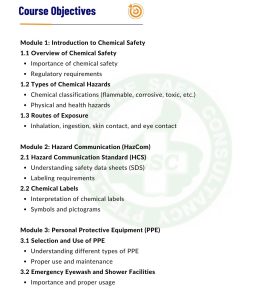

Module 1: Introduction to Chemical Safety

1.1 Overview of Chemical Safety

- Importance of chemical safety

- Regulatory requirements

1.2 Types of Chemical Hazards

- Chemical classifications (flammable, corrosive, toxic, etc.)

- Physical and health hazards

1.3 Routes of Exposure

- Inhalation, ingestion, skin contact, and eye contact

Module 2: Hazard Communication (HazCom)

2.1 Hazard Communication Standard (HCS)

- Understanding safety data sheets (SDS)

- Labeling requirements

2.2 Chemical Labels

- Interpretation of chemical labels

- Symbols and pictograms

Module 3: Personal Protective Equipment (PPE)

3.1 Selection and Use of PPE

- Understanding different types of PPE

- Proper use and maintenance

3.2 Emergency Eyewash and Shower Facilities

- Importance and proper usage

Module 4: Safe Handling and Storage

4.1 Storage Guidelines

- Segregation of incompatible chemicals

- Storage temperature and conditions

4.2 Handling Procedures

- Techniques for safe chemical handling

- Spill response and cleanup

Module 5: Risk Assessment and Control Measures

5.1 Risk Assessment

- Identifying potential risks

- Hazard analysis

5.2 Control Measures

- Engineering controls

- Administrative controls

Module 6: Emergency Response

6.1 Emergency Procedures

- Evacuation plans

- First aid measures

6.2 Fire Safety

- Fire prevention measures.

- Proper use of fire extinguishers

Module 7: Case Studies and Demonstration

7.1 Real-life examples of chemical incidents

- Analysis of incidents and lessons learned.

7.2 Demonstrations of Equipment’s

- Proper use of safety equipment

- Emergency response simulations

Module 8: Regulatory Compliance

8.1 WSH Act, Singapore Standards and Guidelines

- Compliance requirements

- Inspections and audits

8.2 Local and International Regulations

- Understanding regional regulations

Module 9: Best Practices and Continuous Improvement

9.1 Establishing a Safety Culture

- Employee engagement

- Reporting and addressing safety concerns

9.2 Continuous Improvement

- Regular reviews and updates to safety procedures

Module 10: Assessment and Certification

- Final examination Theory 30 MCQ

- Course completion certificate

This course should be adapted to the specific needs of the audience and may vary based on local regulations and industry-specific requirements. Additionally, incorporating interactive elements such as quizzes, discussions, and hands-on activities can enhance the learning experience.

Why should attend Chemical Safety Awareness Course (CSAC)?

1. Enhance Safety and Minimize Risks

- Gain essential knowledge about chemical hazards and their potential risks to health, safety, and the environment.

- Learn how to implement proper handling, storage, and disposal practices to prevent accidents and incidents.

2. Understand Legal Compliance

- Familiarize yourself with Workplace Safety and Health (WSH) regulations and standards related to chemical safety.

- Avoid penalties and ensure compliance with local laws, such as Singapore’s Workplace Safety and Health (General Provisions) Regulations and Environmental Protection Acts.

3. Improve Emergency Preparedness

- Learn how to respond effectively to chemical spills, leaks, and other emergencies.

- Gain skills in using personal protective equipment (PPE) and first-aid measures for chemical exposure incidents.

4. Protect Health and Well-being

- Understand the short-term and long-term health effects of chemical exposure, including irritations, burns, respiratory issues, and chronic conditions.

- Learn measures to safeguard yourself and others against chemical-related hazards.

5. Boost Workplace Productivity

- A safe and well-informed workforce minimizes downtime caused by accidents and incidents.

- Promote a safety-conscious culture, leading to better morale and efficiency among employees.

6. Raise Environmental Awareness

- Understand the environmental impact of improper chemical handling.

- Learn best practices for sustainable and eco-friendly chemical management.

7. Build Professional Expertise

- Enhance your qualifications and competency in handling chemicals safely, making you a more valuable asset to your organization.

- Stay updated with best practices and industry standards for chemical safety.

8. Prevent Financial Losses

- Reduce costs associated with chemical-related accidents, such as medical expenses, legal penalties, and equipment damage.

- Improve resource management to avoid wastage and inefficiency.

Who should attend Chemical Safety Awareness Course (CSAC)?

1. Workers Handling Chemicals

- Employees who work directly with chemicals in their daily tasks, such as in:

- Manufacturing

- Construction

- Laboratories

- Chemical processing plants

- Cleaning and maintenance operations

2. Supervisors and Managers

- Supervisors overseeing teams that handle chemicals or are responsible for implementing chemical safety measures.

- Managers who need to ensure compliance with workplace safety standards and regulatory requirements.

3. Safety and Health Professionals

- Workplace Safety and Health Officers (WSHO) or Environmental Health and Safety (EHS) personnel.

- Safety coordinators or advisors responsible for chemical risk assessments and incident prevention.

4. Facility Operators

- Operators of facilities where chemicals are stored, transported, or disposed of, such as warehouses, storage depots, or hazardous waste sites.

5. Maintenance Teams

- Technicians and maintenance staff who may come into contact with hazardous chemicals during equipment repairs or routine facility upkeep.

6. Laboratory Personnel

- Lab technicians, researchers, and students working with chemicals in research, testing, or educational settings.

7. Emergency Responders

- Firefighters, paramedics, and hazardous material (HAZMAT) response teams who deal with chemical spills or emergencies.

8. Procurement and Inventory Staff

- Personnel responsible for purchasing, storing, or managing inventory of chemical substances.

9. Anyone Involved in Chemical Transport

- Logistics personnel, drivers, or workers involved in the transportation of hazardous substances.

10. Employers or Business Owners

- Employers in industries where chemicals are used, stored, or transported, to ensure workplace compliance and employee safety.

Chemical Safety Awareness Pre-Requisites / Assume Skills and Knowledge

1. Basic Literacy and Numeracy in CSAC

- Ability to read and understand written instructions, labels, and safety data sheets (SDS).

- Basic mathematical skills to interpret chemical quantities, ratios, or exposure limits.

2. Awareness of Workplace Safety

- A general understanding of workplace safety practices and procedures.

- Familiarity with personal protective equipment (PPE) and its usage.

3. Industry or Job Experience (Optional)

- Experience in roles involving handling, storing, or transporting chemicals is beneficial but not mandatory.

- Familiarity with the workplace environment where chemicals are used can enhance learning.

4. Communication Skills

- Ability to communicate clearly and ask questions during the course.

- Comfortable working in a group setting during practical exercises or discussions.

5. Basic Computer Literacy (if online components are included)

- Understanding how to use a computer or tablet to access course materials, especially for virtual or blended learning options.

6. No Prior Chemical Knowledge Required

- The course is designed for beginners and covers foundational knowledge of chemical safety, making prior technical knowledge about chemicals unnecessary.

Trainer to Trainee Ratio

1: 20 (Classroom)

Course Duration

8 hours (Training 7 hours, Assessment 1 hour)

Attendance requirements

100%

Assessment

Written MCQ- Learner must achieve 60%

Training Methodology

Lecture Slides presentation, self-directed learning, e-learning, group discussion, presentation sharing of best practice and incident. Hands on practical session.

Certifications

Upon successful completion of the course a Certificate of Competency will be awarded by Ensure safe Consultancy Pte Ltd.

Course Fees

$100/-

Course Venue

No. 3 Soon Lee Street, #02-05, Pioneer Junction, S (627606).

Contact Details

training@ensuresafe.sg

+65 9680 5878

+65 69777350

Course Schedule

Evening Schedule (Thu & Fri):

3 & 4 APR 2025 (6.00 pm to 10.00 pm)

10 & 11 APR 2025 (6.00 pm to 10.00 pm)

17 & 18 APR 2025 (6.00 pm to 10.00 pm)

24 & 25 APR 2025 (6.00 pm to 10.00 pm)

Saturday Schedule :

5 APR 2025 (1.00 pm to 9.00 pm)

12 APR 2025 (1.00 pm to 9.00 pm)

19 APR 2025 (1.00 pm to 9.00 pm)

26 APR 2025 (1.00 pm to 9.00 pm)

Course Features

- Lecture 0

- Quiz 0

- Duration Lifetime access

- Skill level All levels

- Language English

- Students 1

- Certificate Yes

- Assessments Yes